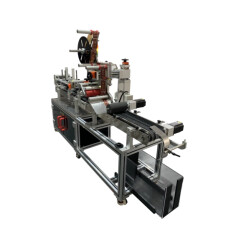

SPM Automatic Packing Line for pre-made Coffee Bags

Fully automatic coffee packing machine

Line include: Packing machine with automatic system Linear-weight Platform Automatic feeder/conveyor Mini conveyor for finished bags - for finished bags adopting & transport, prevent high drop broken bag bottom Z shape conveyor - after mini conveyor for finished bags transport up to top Rotary table for finished bags, prevent drop to floor directly is versatile and can accommodate a variety of packaging types including Stand Up Bags, Flat Bags – Sachets, Flat bottom Bags – Box Pouch, and Gusset Bags. It's perfect for packaging coffee beans in pre-made bags (also with valve), with a maximum dose of 1000g.

The set includes:

- packaging machine

- nitrogen injection

- weighing dose

- MINI belt conveyor (to take packages out of the machine)

- Z-Type belt conveyor (to feed packages onto receiving table)

- receiving table

- pneumatic coffee feeder

Automate packaging: how does SPM reduce the risk of errors?

Automation in coffee packaging machines such as SPM significantly reduces the risk of human error during dosing and sealing. Thanks to precise sensors and advanced algorithms, the process of packaging different types of coffee is not only faster but also more accurate, which translates into less raw material waste and higher quality of the final product.

Consistent coffee packaging quality is crucial to how customers perceive the brand. When each coffee package is identically packaged to the highest standards, customers can be confident in the quality of the product. This consistency builds consumer trust and loyalty, which is invaluable in the competitive coffee market.

SPM integration with the production line: from roasting to sealed packaging

Integrating SPM into the production line requires precise synchronisation of the flow of coffee beans and the packaging process. This makes it possible to maintain continuity of production without unnecessary downtime, which increases the efficiency of the entire process.

The introduction of SPM into the production hall can significantly improve logistics and space organisation. For example, the use of automated conveyors allows for better use of available space and reduces the time needed to transport raw materials and finished products.

Efficiency and ROI: when does the investment in a coffee packaging machine pay off?

Investing in a coffee bag machine can bring a quick return on investment by reducing material losses and increasing the pace of work. Precise dosing and automation of the packaging process minimise waste, which directly reduces production costs.

Factors accelerating the return on investment in an SPM machine include growing demand for coffee products and increased production volume. In addition, aesthetic and branded packaging attracts customers' attention, which can lead to increased sales. As a result, investing in modern packaging technologies becomes a strategic step in the company's development.

Efficiency

up to 8 bags/min

Bags size

250g & 1000g

.jpg/408_286_crop.jpg?ts=1749187135&pn=blog-thumb-small)